IN: REO-USA Line Reactors Provide Key Performance and Market Advantages

REO-USA has a pair of line reactors that other manufacturers can’t match. Like many in the marketplace, the CNW 903 and CNW 905 address voltage and current issues and attenuate harmonics in variable frequency drive (VFD) systems, helping to extend VFD and motor service life. But the company and its parent corporation have gone the extra step for OEM prospects, panel builders and system integrators.

Whether incoming facility power sources are nearby or relatively distant, REO-USA line reactors do more than parrot their counterparts. They can pay big dividends, including energy savings, based on measuring what happens in actual installations. In a typical example, energy savings with a CNW 903 line reactor on a 4kW VFD paid for itself in less than five weeks, achieving savings of nearly $1,000 for the first year alone

“In an industry where precious little down-line data exists on actual application ROI, it’s not about how much it costs up-front. It’s how much it pays long-term,” remarked REO-USA Technical Sales Engineer Alex Ward. “Whether such savings with your own VFD installations are higher or lower, they keep accumulating year after year and that’s the difference with our line reactors.”

The first line of defense in the component chain, line reactor performance affects all components thereafter. Indicative of the commoditized approach common in the industry, however, many manufacturers’ line reactors and load reactors are exactly the same product, right down to the part numbers. Flip a coin and it’s either “line” or “load”, but not so with REO-USA says Ward.

“We make line and load reactors differently. We put more carefully selected ‘build’ material into our 3-phase line reactors, providing more inductance per phase,” revealed Ward. “They’re specifically designed to more effectively handle line-side voltage and current issues, reduce harmonic ripple and minimize distortion from EMI (electromagnetic interference).”

This makes sense because the “line” side is where voltage spikes. Any installation can benefit from extra protection to turn powerful surfer-style waves into gentle swells lapping at the beach, before they reach a VFD or motor. In the process, REO-USA line reactors keep VFD input terminal noise level low enough to help drives meet the IEEE 519 standard for preventing interference between electrical components.

Noting the almost endless array of VFD applications, Ward observes: “Now engineers can design greater protection along with savings into a host of next-generation products; from HVAC, machine tools, robotic equipment, elevators, printing presses, pumps and food processing lines, to renewable energy systems, electric and hybrid vehicles, railway equipment and more, while helping to extend VFD and motor life .

Over time, harmonics issues or voltage spikes often arise on the input with existing installations. Ward said in many cases there is no room for a line reactor inside the cabinet.

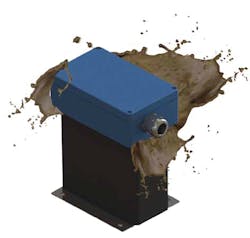

“Don’t overlook retrofit opportunities because here’s where our NEMA 4X-rated reactors with patented encapsulation are a godsend. System integrators can put REO-USA line reactors outside the box with no problem. They withstand rain, sleet, freezing conditions, dust, sand, saltwater and other corrosive conditions.”

Outside the converter or inside the box, outdoors or inside, retro or all-new, there’s no better solution on the market today for substations, railway, petro-chemical, marine, food processing and other applications.

Reactor options also match impedance needs

While sharing inductance, patented encapsulation and related performance advantages, one key way in which REO-USA 3-phase CNW 903 and CNW 905 line reactors differ is in impedance value, enabling engineers to precisely match particular product needs.

CNW 903 impedance, for example, is 4%Z. Two dozen reactor types are available with rated voltage (V) up to 3 x 480, and rated current (A) from 3 to 1600. More than 30 CNW 905 types are offered (2%Z impedance value), with rated voltage (V) also up to 3 x 480, and rated current (A) from 1.5 to 1600.

“While design engineers, panel builders and system integrators understandably gravitate toward familiar suppliers, our line reactors offer advantages well worth considering,” sums up Ward. “They can contact us directly for product details and quotes and see for themselves how superior inductance, patented protection and demonstrated payback potential can help them take products and installations to a new level.”