Batteries, hydrogen and the pursuit of zero-emissions transit

As transit agencies push toward more sustainable solutions for their net-zero goals, battery-electric and hydrogen fuel cell buses are becoming more prevalent.

While each type offers different paths to more sustainable operations, they present transit leaders with three common operational priorities that must be addressed: workforce training, safety enhancements and resilience considerations.

Both types store energy on board to power an electric motor that propels the bus. However, unlike batteries, fuel cells do not require recharging from the grid. Instead, they produce electricity continuously from hydrogen fuel stored on top of the vehicle as a high-pressure gas. This is similar to how compressed natural gas (CNG) buses store their fuel, but at an even higher pressure.

Although upfront capital costs for battery-electric and hydrogen fuel cell vehicle purchases and infrastructure requirements are higher than their diesel or CNG counterparts, significant operational savings can be realized from this investment in the long term, in addition to the many environmental benefits associated with zero-emission fleets.

In the past decade, battery buses gained an early lead over hydrogen buses in the transit market, but interest in hydrogen has sharply increased in recent years. One reason for this growing interest in hydrogen is that capital costs for hydrogen fueling and storage buildout can be lower than battery electric charging infrastructure, especially at a larger scale.

Careful evaluation of options is paramount before pursuing zero-emission alternatives. Part of determining the path forward is a comprehensive plan for workforce development, which includes a thorough gap analysis and carefully considering safety and resiliency factors for battery-electric and hydrogen fuel cell buses.

Planning workforce training

Workforce development is crucial for successfully implementing these alternative fuel sources. Typically, as a first step, we recommend a gap analysis for an agency’s staff and training processes. The needs in workforce development are often similar for both battery-electric and hydrogen fuel cell buses.

While these are relatively new technologies for some agencies, they’re not completely foreign to their workforces. There are general skills and safety measures for handling modern vehicles that are applicable to buses powered by both technologies.

The more likely gaps an analysis would uncover involve electricity fundamentals. Both battery-electric and hydrogen propulsion require a solid grasp of electrical troubleshooting and theory to accurately diagnose and repair any issues. To that end, a self-assessment survey by an agency works well to determine how comfortable a workforce is with electrical diagnostics, using computers to diagnose vehicle issues and handle high-voltage electrical systems.

Hydrogen fuel cell buses, like battery-electric buses, need high voltage electrical troubleshooting and require training for the hydrogen storage and fuel cell system.

There are some minor differences for operators behind the wheel that, while not major, still require training for optimal performance. Regenerative braking, for instance, allows the vehicle to slow down as the accelerator pedal is released, minimizing the need to switch between accelerator and brake pedals.

While it is crucial that an agency’s workforce understands and respects high-voltage systems, they don’t need to fear them, as they are perfectly safe when maintained properly. Early focus on ensuring confidence in the workforce greatly improves project success.

Making safety a priority

The common safety consideration for both technologies is their high voltage systems. Operators must be aware of faults, errors and warning signals on their dashboards, and what they mean. They should know what steps to take if these indications appear. Any agency that’s implementing either technology should have standard operating procedures for dashboard warning indications.

Since both types of buses utilize high-voltage battery systems, maintenance technicians must be trained for safety against potential risks. The standard procedures and inherent design features of these buses tend to eliminate the potential for any incidents. With proper training and proper personal protective equipment, one can safely work on these vehicles.

Data suggests fire risk in these types of vehicles is lower than diesel-powered buses, but fires can be more difficult to extinguish when they occur. In buses with HV batteries, the enclosed nature of the battery box—which can produce fuel, oxygen and heat—makes it hard to get enough water on the fire to put it out quickly. Hydrogen fires, too, are challenging. They burn invisibly, which makes detection and extinguishing more difficult.

Modern electric and hydrogen buses are designed with the proper sensors and safety systems to mitigate these concerns, such as hydrogen detectors and automated leak check systems for hydrogen fuel cell buses and sophisticated warning sensors on electric buses.

Understanding resilient alternative fuels

Resiliency is another crucial aspect to consider when agencies evaluate their zero-emission choices.

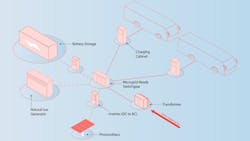

For battery-electric buses, it’s important to know how frequently grid outages are occurring in the agency’s operations area, as well as their average duration to help determine resource expenditure for increased resiliency. Microgrids, which often include solar arrays and stationary storage, can enhance resiliency by providing local energy production. Microgrids can operate independently, saving money and reducing an agency’s reliance on a local utility. It is also common to include a generator as part of a resiliency system.

The tricky part with hydrogen fuel cell buses is securing the hydrogen, which is most often produced through steam methane reformation (SMR) and has associated carbon emissions that can set back an agency’s net-zero goals. However, low-carbon production methods are growing. A benefit to hydrogen is that a few days’ worth can be stored onsite. Typically, in the event of a power outage, on-site generators are recommended to power fueling stations when needed. Larger-scale emergencies could impact hydrogen deliveries.

There’s also a growing interest in bolstering hydrogen’s resiliency nationwide through programs like the Department of Energy’s Regional Clean Hydrogen Hubs (H2Hubs) Program, which aims to create a national network of connective hydrogen infrastructure.

Evaluating agency-specific solutions

There’s no clear-cut, better choice in zero-emissions technology for any given agency. It all depends on the agency’s specific goals and needs, which requires a detailed evaluation that goes beyond standard considerations.

Agencies should consider questions such as:

- What is the distance a bus needs to travel? In a sprawling city like Denver, buses may need to cover more than 300 miles daily, which may not be suitable for an electric bus. However, for shorter distances, like 150 miles, battery-electric buses could be ideal.

- How will the agency need to prepare its facility for a chosen technology? For battery-electric buses, there must be a reliable power supply, which could mean installing micro-grids. For hydrogen fuel cell buses, the main concern is sourcing the hydrogen itself and managing its cost.

- Is the facility designed to handle lighter-than-air gases and have features like vent doors and ceilings that prevent gas pockets from forming?

Each agency should explore numerous other considerations when evaluating the requirements and objectives of battery-electric and hydrogen fuel cell buses. A focus on workforce training, safety and resiliency will open a path to successful outcomes.

About the Author

Mike Finnern

Mike Finnern is a senior vice president and national zero-emissions fleet lead at WSP in the U.S.