The mandate for positive train control (PTC) is driving significant upgrades in the electronic control infrastructure of the American railroad industry. Traditionally, most equipment in wayside signal bungalows consisted of electromechanical control circuitry. With the move to PTC, however, freight and passenger rail lines need to expand implementation of microprocessor-based electronic circuitry.

The ongoing upgrades to meet the new requirements have uncovered the need for a higher functioning and more cost-effective solution to lightning protection within the wayside railroad bungalow environment. The sensitive electronics behind PTC are more susceptible to the effects of lightning strikes than legacy electromechanical control circuitry.

Legacy Surge Protection

The basic design of surge protective devices (SPDs) used in the railroad industry has remained largely unchanged since the late 1940s. These Association of American Railroad (AAR)-style devices are based on spark-gap technology.

The SPD is used in conjunction with a terminal mounting block. The terminal mounting block consists of three, four or five binding post configurations (14-24 thread) depending on position and usage. Wire bending techniques, ring tongue terminals, loose washers and nuts are used to connect wires to the binding posts. The SPD is mechanically connected between two of the binding posts.

Some bungalows have as many as 100 SPDs installed to protect the signal and communication circuitry. Subsequent to the mounting of the SPDs in the bungalow, the installer must terminate the field and case wires. The user strips back the field and case wires, trims the wire insulation, forms a ring tongue out of bare wire or crimps a ring terminal onto the bare wire and then connects the wire to a post with a nut.

Periodically, the AAR devices must also be tested on site to determine their minimum insulation resistance (IR) value. The orange field wire is tested with a megohmmeter. Testing requires the removal of the blue case wire and the ice cube element from the circuit. After the tester removes the gold nut — which disconnects the connection link, he or she connects the megohmmeter between the field wire post and ground reference to measure the insulation resistance between the two. Once testing is complete, everything must be reattached.

If an individual AAR SPD in a bungalow fails due to a lightning strike or other voltage surge, it must be replaced. Inspectors are required to visit bungalows for visual inspection periodically or after a known lightning strike. If that inspection shows that 30 percent of the SPD appears to be covered by carbon, the SPD must be replaced.

To replace a failed SPD, all power to the bungalow must be shut down. The installer removes all of the mounting hardware from the ground, field and case wires, and the failed SPD from the inline circuit. He or she mounts a new SPD onto the correct terminal block post and reassembles the mounting hardware onto the terminal block posts. Finally, the assembly is put back into the inline circuit, and the bungalow protective circuit is reenergized.

A Modern Approach

As railroads upgrade the technology in their bungalows to IC-based equipment to meet the PTC requirements, surge protection solutions will need to meet more demanding electronic and mechanical performance criteria. Electronic circuits associated with PTC systems have a higher sensitivity to lightning strikes and voltage surges and require faster response time and lower let-through voltage at the SPD level. Associated mechanical improvements are also needed to shorten the time required for equipment practices in order to meet more vigorous cost targets as a result of PTC implementation.

For the first time in more than 60 years, railway operators have a new option to protect wayside equipment from surges.

Comparison of Electric Characteristics of Legacy versus Modern Wayside SPDs

| Legacy Wayside SPDs | Modern Wayside SPDs |

| Surge protective device technology: spark-gap based | Hybrid MOV and gas tube technology |

| Operating voltage: 0 to 50-volt DC | Operating voltage (Un): 100-volt DC |

| Breakdown voltage: 700 to 1000 volts | Breakdown voltage: 1.4 kilovolt |

| Discharge current: 50 kVA max | Discharge current: 20 kVA (lmax) |

| Let-through voltage = 2500-volts nom | Let-through voltage: 450 Volts |

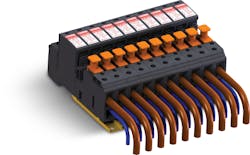

The modern SPD is an MOV-based device consisting of a two-piece design:

– A base element that contains wire and base attachment features, testing features and an available remote monitoring feature.

– A removable plug that can be designed for different applications, including track circuits, track equalizer circuits, relay circuits and digital circuit applications.

The design of the base element incorporates several features to minimize installation time and maintenance time, without losing the robustness of the connection. Features include:

– A cavity on the upper left side of the unit for the attachment of the field wire, using a rising cage screw clamp.

– A cavity on the lower left side of the unit for the attachment of the house wire, also using a rising cage screw clamp.

– Z-axis tool actuation slots on top of left side of the base for tightening cage screw clamps and securing field and house wires.

– A pull-disconnect/push-connect post feature located on the top left side of the base that facilitates efficient high-pot testing of the field wire.

– The disconnect post is alligator clip accessible during the high-pot and ground testing.

– DIN rail-mount slot at the center of the base for securing the assembly to the DIN rail.

– A cavity on the upper right side of the unit for the attachment of the ground wire, using a rising cage screw clamp (#20-#2 AWG). A tool actuation slot is provided on the top of the right side of the base for tightening the rising cage screw and securing the ground wire and optional ground busbar.

– A three-position connector on the lower right side of the base to provide connection to an available remote monitoring feature of the unit. The remote monitoring feature provides real-time data feedback during operation of the unit.

Pluggable Protection

The base element accepts plugs with different voltage ratings to meet the unit’s specific application (for example, different aspect circuits, track circuits, track equalizer circuits, relay circuits, track switch motor circuits and digital circuits.) Each plug is keyed according to its voltage rating to prevent incorrect plug voltage installation.

In addition to the electrical characteristics already discussed, advanced design features can enhance safety and the operation of the assembly and reduce the maintenance cost associated with the product. These features include:

– A thermal disconnect to prevent a thermal runaway condition in case of a product fault condition.

– A visual fault indication for positive indication of a failed plug.

– Lower let-through voltage.

– Fail open.

Equipment Practice Comparisons

Following is the time required for initial installation of an existing AAR SPD on the shop floor and then the time required for trackside bungalow installation. That total installation time is then compared to the time required for an equivalent installation of a BE-AR product base.

One-Circuit Device Installation Time Comparison

| Existing AAR SPD Equipment Practice |

BE-AR SPD |

||

| Install three AAR terminal blk assm | 120 secs* | Install DIN rail | 20 secs* |

|

|

Attach BLKFT module |

2 secs* |

|

| Secure screw | 5 secs* | ||

| Strip FIELD wire | 10 secs** | Strip FIELD wire | 10 secs** |

| Fit & form ring tongue to FIELD wire | 20 secs** | ||

| Install ring tongue onto posts | 10 secs** | Install FIELD wire |

5 secs** |

| Strip CASE wire | 10 secs* | Strip CASE wire |

10 secs* |

| Fit & form ring tongue to CASE wire | 20 secs* | ||

| Install ice cube | 30 secs* | Install SPD plug | 2 secs* |

| Install L-bracket | 5 secs* | ||

| Install & torque 5 retaining nuts | 45 secs** | ||

| Per circuit installation time | 155 secs | Per circuit installation time | 39 secs |

| * =shop floor installation, ** = bungalow installation | |||

As the data shows, the new method is 116 seconds faster per circuit. For a 20-circuit module, the resulting time difference would be 2,320 seconds or 38.6 minutes, a significant reduction in time and labor costs.

Field Test Time Analysis

As discussed earlier, AAR SPDs require periodic testing to ensure they are still functioning. The device is tested for minimum insulation resistance (IR) value between the field wire and a ground reference.

To test the AAP SPD, the installer must first remove the brass float nut, and then replace the brass nut and torque, which takes about 15 seconds. Testing the plug-in SPD, however, only takes about two seconds — one second to lift the disconnect post, and one second to lower the disconnect post.

Difference in Testing Times

| Existing AAR SPD Equipment Practice |

BE-AR SPD |

||

| Remove brass float nut | 10 secs | Lift disconnect post | 1 sec |

| Replace brass nut & torque | 5 secs | Lower disconnect post | 1 sec |

| Time to execute ohmmeter test | 15 secs | Time to execute ohmmeter test | 2 secs |

If a bungalow contained 20 circuits, this 13-second time differential for a single circuit would increase to a 260-second, or 4.3-minute advantage.

Visual Inspection for Carbon

To determine if an AAR SPD has failed, an inspector needs to look at the inside of the plastic of the ice cube housing. If it looks like carbon residue is covering 30 percent or more of the inside of the housing, the module must be replaced, whether it still functions or not.

On the newer style of SPDs, a flag indicates if the module has failed. It is much quicker to glance at a flag and see if it’s on than to perform a close inspection of the ice cube case. This will aggregate into a significant difference over a 20-circuit module.

Perhaps more importantly, the flag gives a definite answer about whether or not the module has failed. This eliminates the guesswork and costs of unnecessary replacement parts. Remote monitoring capability can further reduce the inspection time. The inspector no longer needs to visit the bungalows “just in case.” If the SPD has failed, it can send a signal to a set of local contacts notifying the operator that the module must be replaced.

SPD Field Replacement

Replacing a failed AAR module in the field is a cumbersome process involving setting up a track clearance time, de-energizing the affected circuit, and removing and replacing the failed module. Based on the installation time figures in the previous table, removing and replacing a module will take about 180 seconds — which does not include additional time to clear the track and de-energize the cables.

The modern module is hot-swappable; that is, the base can stay in place while replacing the failed module. There is no need for track clearance or de-energizing the track circuit. Changing the plug module takes about four seconds. Again, adding up the cumulative time for a 20-circuit module, the newer technology could save an estimated 58 minutes.

Protection in the PTC Environment

Modern wayside equipment needs modern protection. Railway operators cannot afford the downtime that a lightning strike or other surge can cause to the sensitive electronics that PTC requires.

An MOV-based SPD with lower electrical let-through voltage will enable the proper functioning of microprocessor-based PTC electronics. Features such as hot-swappability and remote sensing can further reduce downtime. Implementing this new approach into a wayside lightning protection network will not only improve reliability, but save significant labor and maintenance costs in the PTC environment.

John Moore is senior business development manager — Transportation Infrastructure, with Phoenix Contact.

James Schroeder is president of Schroeder Consulting Services.