Digital Transformation Drives Innovation in Transportation

Unrelenting population growth, rapid urbanization, government investment in new road and rail networks, evolving social and environmental priorities as a result of the urgent need to act on the effects of climate change—all these situations put the transportation industry at the heart of the global disruptions that we are experiencing.

The truth is that building better infrastructure and building infrastructure better really do have the potential to change the quality of life for the world’s population. The evidence was plain to see on a recent business trip to Jakarta, Indonesia. Currently the largest city in southeast Asia, its greater metropolitan area is already home to more than 11 million people, making it the second most populated urban area on planet earth.

Air pollution has long plagued the greater Jakarta area, which is now ranked among the 10 most polluted cities globally. While manufacturing and coal-fired power plants have contributed to the poor air quality in the past, its significant population density causes massive congestion on its roads, with government research showing vehicle emissions account for around 44 percent of air pollution.

While vehicle use is already regulated and there are talks of random vehicle emission tests, the Indonesian government has clearly recognized that sustainable transportation must exist beyond the greater Jakarta area.

Whether looking at PT MRT Jakarta, a past winner in the Bentley Systems Going Digital awards Rail and Transit category, who worked on MRT Jakarta Phase 2a to extend the city’s mass rapid transit system, or 2023 Finalist in the Roads and Highways category PT Waskita Karya, who worked to relocate the country’s capital to Nusantara, Borneo, one thing is clear: Bentley technology, through visionary users, is helping to deliver infrastructure that will truly change the lives of millions of Indonesians.

These challenges, however, are not peculiar to southeast Asia. Owner-operators and supply chains around the world are constantly battling with aging assets, tighter budgets, skilled labor shortages, increased project complexity and their contribution to decarbonizing the transportation industry. Now more than ever before, it is critical everyone in the industry grasp the opportunity that going digital provides.

The future is happening now

To succeed in increasing the levels of service, safety and reliability that the traveling public today both demands and deserves, organizations need timely access to data that they can trust. In addition, they need innovative solutions that enable data-centric digital workflows to streamline activities, deliver the insight needed to make better decisions and realize better business outcomes.

Due to the massive amounts of data generated by technologies—including cloud services, the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML)—recent years have seen a surge of interest in how digital twins can transform the way infrastructure is planned, developed, built and operated.

Born at NASA in the 1960s as a “living model” of the Apollo mission, digital twins are neither new, nor the stuff of science fiction. In transportation, infrastructure digital twins are realistic, dynamic digital representations of physical assets, processes or systems in the built or natural environment.

Continuously updated in near-real time from sources that include surveys, inspections and IoT-connected sensors, digital twins represent state, condition, location and performance. They provide real-time views of critical information in the built world to better inform stakeholders with insights that improve the way that we envision, construct, operate and maintain these systems.

The ability to visualize assets, check status, optimize performance and predict failure through digital twin technologies provides the visibility and insight needed to let data drive better decisions. It is the data in digital twins that are the foundation for infrastructure intelligence.

Take Denver, Colo., which puts walkable neighborhoods at the heart of its complete transportation system, lessening the need for more carbon-emitting forms of travel and promoting more active living. The availability of pedestrian bridges is crucial. If shut for repairs, pedestrians can find themselves unable to access critical services and recreational activities.

With 630 bridges to keep safe and passable, Courtney Shepard, bridge asset manager for the City and County of Denver, has her hands full regularly inspecting and maintaining these critical links. In parallel, John Barone, infrastructure technology lead with Stantec, was thinking of ways the engineering firm could leverage technology to deliver new levels of service and value to its clients.

Having worked together previously, Shepard and Barone decided to embrace the opportunity that going digital provided, feeling the lessons learned could be scaled to become the basis for a digital twin that encompassed an array of assets. Both wanted to go beyond simply visualizing an area’s real-world context to include IoT-connected devices that produce continual data into real-world conditions.

They quickly determined Highland Bridge would be the ideal starting point for gathering data that would help operations and maintenance teams improve decision-making. Connecting pedestrians in the Highland neighborhood to downtown Denver, the span crosses Interstate 25, rail lines and the South Platte River.

Shepard and her team were most concerned about bridge vibrations so Stantec installed sensors with accelerometers and tilt meters to capture the dynamic movement of the structure. With sensors secured into place using clamps and adhesive, Bentley’s iTwin® IoT was used to bring together sensor data in one location.

Stantec’s sensors now provide daily data on Highland Bridge’s performance and can send alerts to the team if movement exceeds specific parameters. This digital twin means that at any given time, the City and County of Denver knows the current state of the bridge, helping them target specific maintenance and avoid the need for extended shutdowns.

With so much data being captured, created and stored on transportation assets, often in siloed systems and multiple formats, it is imperative organizations have an efficient way of making it accessible to all stakeholders. Also critical is the people viewing the data need to understand its context so it can be analyzed to provide insight and inform decision-making.

AI and ML are also expected to have a big impact on infrastructure. Automated analytics will have an important role in making sure the right data is visible in the right application. However, it is generative AI (GenAI), which learns the patterns and structure of inputted data to generate new data with similar characteristics has the biggest potential to transform workflows.

Following announcements at last year’s Year in Infrastructure and Going Digital Awards event, we introduced iTwin Experience, iTwin Capture and iTwin IoT as a family of products that enable our users to create and curate digital twins. In response to the specific challenge of ageing infrastructure, we also introduced a new bridge monitoring solution leveraging these products.

The Collins Engineers, Inc.’s Robert Street Bridge project is a great example of this monitoring solution in action. Nationally registered as a historic structure, Robert Street Bridge is a reinforced concrete arch bridge that crosses the Mississippi River. To address significant structural deterioration, Minnesota Department of Transportation (MnDOT) initiated a bridge rehabilitation project and retained Collins Engineers to perform a detailed bridge inspection.

The project required accurate collecting of detailed inspection information that traditional methods and previously used software could not accommodate. Collins Engineers wanted to supplement conventional workflows with AI-powered digital twins. Barritt Lovelace, vice president of UAS, AI, and reality modeling at Collins Engineers, and his team used Skydio drones to collect data on the bridge before post processing it in iTwin Capture to create a digital twin of the bridge, then uploading it in iTwin Experience.

Collins Engineers then used AI to automatically detect defects, including cracks and spalls, so that inspectors could pre-inspect the bridge in the office to get as much information in the digital twin as possible—saving time and expense versus doing this in the field. In addition to the increased ease and speed of data collection and analysis, this digitally enabled workflow also delivered quality improvements, allowing senior engineers to review and perform a quality review of the inspection data directly in the digital twin.

Leveraging digital twins for inspection through Bentley’s bridge monitoring solution meant that the data could be shared with the entire team due to the centralized inspection, inventory and testing information. As Collins Engineers and MnDOT work through this important bridge rehabilitation project, the team expects to see a minimum of 20 percent in construction savings, stemming from the improvements in the quality of data collected and better decisions enabled through digital twin workflows.

Redefining the new normal

While recognizing that digital twins are still relatively new, the evidence shows they are already transforming the way that our users work. However, at Bentley, we believe digital transformation has less to do with a destination and more about how organizations navigate, respond and evolve to challenges faced over time.

It is particularly important in transportation infrastructure, given that projects often span many years and continue to grow in complexity. Throughout the planning, design and construction of a road, railway, bridge or tunnel, projects require effective collaboration among specialist disciplines and engagement with internal and external stakeholders, including members of the public.

With building information modeling standards and workflows now part of nearly everyone’s new normal, we still see the continued reliance on common data environments (CDEs). CDEs that span the entire lifecycle provide a single view of the truth that can be used in critical decision-making, as well as are a fundamental part of why we introduced Bentley Infrastructure Cloud.

Unifying our industry-leading design, build and operate capabilities, and now powered by iTwin, Bentley Infrastructure Cloud helps teams unlock the full potential of their data. Providing visibility and access to critical project and asset information, it blends file and document-driven workflows to enhance collaboration, as well as provide support for many CAD/industry formats, including IFC.

Bentley Infrastructure Cloud also targets the removal of communication breakdowns on design and build projects, providing direct access to document and deliverables management, design and construction reviews, clash and design validation, 4D scheduling, 5D/6D costing and performance monitoring and field integration—all via cloud services.

This integrated approach means design models can be used as the foundation for construction models, allowing teams to collaborate iteratively on the same data. A good example is AtkinsRéalis’ Going Digital Award submission that features the I-70 Floyd Hill to Veterans Memorial Tunnels project. This Colorado Department of Transportation project provides roadway improvements to enhance safety and reduce crashes on an eight-mile section of I-70, which is prone to severe congestion and bottlenecks.

The team used digital twins to improve visibility of challenges faced by the many disciplines and stakeholders involved. Bentley’s open applications helped to facilitate collaborative modeling while ProjectWise saved $1.2 million on the project and helped manage more than 1,000 file sheets, 5,500 hours in coordination time and 97 percent of effort developing and publishing digital twins for review. AtkinsRéalis was also able to convey design intent, foster community integration and mitigate environmental and social impact.

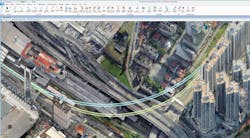

An example from the Rail and Transit category is the Johor Bahru–Singapore Rapid Transit System from AECOM. Connecting Johor Bahru in Malaysia with Woodlands, Singapore, this project spans two countries and features stations on both sides of the border, each with customs, immigration and quarantine facilities. When complete, the line will reduce vehicular use of the Johor-Singapore Causeway, providing greener transportation for around 10,000 passengers per hour.

To facilitate collaborative workflows and establish optimal project delivery, AECOM adopted a digital twin approach, leveraging Bentley’s integrated digital modeling and analysis applications. The team developed a reality mesh from drone-captured images, accelerating survey and processing fivefold. They also established a CDE using ProjectWise to optimize planning, design and construction while Bentley’s open applications helped automate workflows, ensure structural integrity and save 50 percent in drafting time.

Enabling the next generation

With much of the world’s transportation infrastructure in use beyond its initially designed lifespan, monitoring solutions, coupled with advanced analytics, including AI and ML, will become increasingly important to ensuring the safe, reliable, resilient and sustainable operations of networks into the future.

This past August, Bentley Systems’ iTwin Ventures acquired Blyncsy®, a Salt Lake City, Utah-based provider of AI services for departments of transportation to support operations and maintenance activities.

Leveraging dash cam footage from thousands of cars to build its machine learning model, Blyncsy applies computer vision and AI to identify maintenance issues across roadway networks. Replacing costly and often slow manual data collection workflows, it can detect anything from potholes to traffic light outages, vegetation conditions and other safety issues, including the location of active work zones.

Blyncsy will adopt Bentley’s iTwin Platform for immersive integration with infrastructure owners’ engineering and simulation models to further improve owner-operators’ awareness and timely mitigation of road conditions while Bentley will incorporate Blyncsy’s disruptive AI services within its emerging mobility digital twin offerings, providing deeper asset analytics to meet the challenges owners face now and in the future.

Driving innovation by going digital in transportation

There are many commonalities across these innovative projects. Principally though—whether in the hands of inspectors of bridges, designers of new transit systems or the maintainers of existing road networks—it is clear that, as an industry, we must take advantage of the huge opportunity digital technology and transformation offers to ensure our future success.

Integral to this success is visibility and timely access to trusted data through digital twins—particularly due to their ability to drive data-based decisions that help infrastructure professionals deliver different and improved outcomes. Enabling increased efficiency, enhanced quality and reduced risk, the data in digital twins is the foundation of infrastructure intelligence, helping deliver the safety, service and sustainability levels that are critical to our industry’s future success.

While we are still in the relatively early stages of the disruption that digital twins will cause in our industry, they are changing the way that our users are working today. No one can be sure where they will take us, but I am convinced that digital twins with AI—as a means of providing intelligent, data-driven solutions to the industry’s most complex problems—will build on existing momentum with increasing velocity, ultimately becoming a key tool in the working lives of engineers the world over.

The future is very definitely happening now. With their potential to redefine our new normal, digital twins will empower the next generation of industry professionals to build better infrastructure, and, in their hands, help build infrastructure better, so that the quality of life for millions of people is changed forever.

About the Author

Steve Cockerell

Industry Marketing Director for Transportation, Bentley Systems

Steve Cockerell is the industry marketing director for transportation at Bentley Systems. He joined Bentley in 2002 through the company’s acquisition of Infrasoft and has worked to deliver knowledge and expertise to users in the transportation industry. Cockerell has more than 20 years of industry experience, which he began by studying civil engineering and working as a highway designer for local government in the U.K.