Vehicle Design: Managing Wheel/Rail-Generated Noise and Vibration from the Ground Up

Vibration and noise are an intrinsic part of rail transit operations. Vibration and the noise generated as a result can generate complaints, disrupt sensitive scientific equipment in nearby buildings and damage or accelerate wear in components of the vehicle and track itself. There are many tools transit systems use to mitigate vibration and noise, including sound barriers, lubrication and rail grinding, but much of this mitigation occurs before the wheel even meets the track. It is done during the track and vehicle design process. Wheel/Rail Seminars convened a group of experts, including a transit operator, three vehicle manufacturers and a noise and vibration consultant, to examine how to mitigate wheel/rail-generated noise at the source from the vehicle perspective at the WRI ’23 Rail Transit conference, of which Mass Transit is the Presenting Sponsor.

Rail transit vehicles are highly specialized. Every fleet is built to exacting specifications and designed for its unique operating environment. A key characteristic that drives new vehicle/car design is vibration. Vibrations generated at the vehicle/track and wheel/rail interfaces cause noise, wear and damage. The car builder has an important role to play in minimizing noise and vibration at the source.

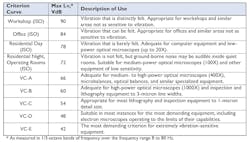

Vibration (and noise produced because of vibration) is one of the Federal Transit Administration's (FTA) criteria that transit systems in the U.S. are beholden to. Some transit systems maintain their own, more stringent thresholds and although there are many vibration and noise mitigation techniques that transit systems employ — including track design elements, wheel rail interface management and path control, such as vibration isolation and noise barriers — much of the mitigation is done on the front end at the design level. Vehicle design is a key factor in reducing and eliminating noise and vibration issues.

Designing and optimizing a vehicle is no small feat. There are many other criteria that car builders must meet before considering the noise and vibration implications of the design including speed, performance, steering, stability, service-proven design standards and ease of maintenance. Shankar Rajaram, executive project director at Sound Transit, told attendees at the WRI ‘23 WRI Rail Transit Conference that ”all these boxes have to be checked while you’re trying to optimize your vehicles and trucks.”

He explained there are several vehicle design factors that influence vibration and noise: Primary suspension stiffness, unsprung mass, resilient wheels (wheels with elastomeric tyres to help damp vibration), carbody connections, axle spacing, solid axles versus independently rotating wheels and the wheel/rail profile match. Rajaram explained that once a vehicle goes into operation, factors such as wheel flats and out-of-roundness and wheel/rail surface roughness can also contribute to high vibration events.

Of these variables, unsprung mass and wheel flats tend to contribute most to the magnitude of generated vibrations, added Briony Croft, an acoustic engineer and director at Sahaya Consulting (Canada) and Acoustic Studio (Australia).

“Unsprung mass, a known contributor to noise and vibration, is a variable that can only be adjusted in the design phase,” Croft said.

Even then, Croft noted findings by the European Union Rail Induced Vibration Abatement Solutions project found a 25 percent reduction in unsprung mass results in an average broadband vibration reduction of only 1 to 2 dB. Achieving a 6 dB vibration reduction could require as much as a 50 percent reduction in unsprung mass, which may not be practical in many cases. So, while minimizing unsprung mass is the first step to controlling noise and vibration from a design standpoint, it is only one of many variables.

Regarding primary suspension, conventional wisdom is that it should be relatively soft. Rajarmam explained the FTA Transit Noise and Vibration Impact Assessment Manual states that if a vehicle’s primary suspension resonant frequency is 15 Hz or higher, the base operational noise level predictions should be increased by 8 dB. A soft suspension is desirable but a too soft suspension can cause stability issues and negatively affect ride quality.

“In my experience, 10 Hz to 13 Hz eigenmode (a normal mode in an oscillating system in which all parts of the system are oscillating with the same frequency) seems to be the optimal range in terms of stability, noise and vibration,” Rajarmam said.

Rajaram also noted the FTA figures are predictive guidelines and that previous studies have shown that differences in suspension stiffness are more likely to cause a shift in the frequency of vibrations, rather than a change in magnitude.

In addition to these factors, there are adjacent elements like track condition and wheel/rail profile design that affect the car builder’s analyses and calculations during the design phase and continue to play an important role in vehicle performance long after the customer has taken delivery.

Vehicle procurement is a complex process. On top of these conditions, the specifications that transit systems set for vehicle procurement continue to grow more stringent, particularly regarding noise and vibration. These improvements are made possible by vehicle designers and builders leveraging new technologies and materials to push the performance envelope as far as possible and by the refinement of noise and vibration measurement and prediction techniques.

Sound Transit, for example, has developed its own vibration criteria for vehicle procurement. According to Rajaram, the Y-axis shows 1/3 Octave band frequency in hertz and the X-axis shows force density level in decibels, a metric used by the FTA to determine vibration generated at the source, independent of external factors. Per Sound Transit’s contract, every new vehicle delivered to the agency is tested and must meet this specification. The measured vibration data also shows two peaks – one at 20 Hz and one at 63 Hz. Subsequent analysis indicated the 20-Hz peak was related to wheel out-of-roundness while the 63-Hz peak was related to wheel surface roughness.

Rajaram notes at one point in their monitoring, multiple trains abruptly began to exceed their vibration threshold in the 63-Hz range. It was later determined this was due to a mis-calibrated wheel truing machine that was introducing significant surface roughness. Once this was corrected, vibrations returned to acceptable levels.

A strong foundation

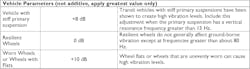

Light-rail vehicle truck designs can be subject to many different requirements depending on the customer. Sergio Perez, manager of Carbody and Truck Engineering and Development at Stadler Rail Valencia, explained the requirements can take the form of comparative analysis, such as equivalence or improvement over current vibration measurements, absolute requirements like a specified value for noise or vibration and requirements defining the product parameters like unsprung mass or use of resilient wheels. Comparative analysis can be particularly challenging to assess without extensive analysis. Perez said that without knowing the transmission path or characteristics of ground-borne vibrations, it’s difficult to design a solution.

Absolute requirements, such as those that Sound Transit uses in its procurement specification for ground vibrations, are often based on FTA Transit Noise and Vibration Impact figures (in the U.S.). According to Perez, ISO 2631 is also used as a ground vibration reference, though typically oriented toward on-board ride quality.

Requirements defining vehicle parameters can be beneficial in scenarios where a customer has previously implemented a vehicle-based solution to resolve an issue and wants to replicate that success.

“These types of requirements have major implications for the design phase and may even be in conflict with one another and it’s important to consider the effect of each component on the vehicle as a system; a component or parameter optimized for one specific vehicle may be sub-optimal in another,” said Kevin McClain, director of mechanical systems engineering at Siemens Mobility Inc.

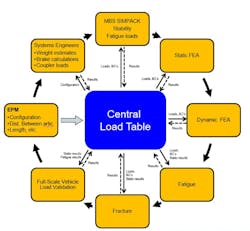

McClain went on to note that once a car builder begins a project, it tends to follow a prescribed lifecycle and while the details and specifications of each project vary, the process does not. Within the project lifecycle, car builders work with a tremendous amount of data. Every point of data, whether taken from the specification, theoretical calculations or simulations, finite element analyses or full-scale testing, helps to improve the end-result: The vehicle. Whether they are collecting it or not is provided by the customer, car builders depend on accurate and readily available data to deliver an optimized vehicle on spec and on time.

Due to the several components that make up a vehicle and because so many variables affect vehicle performance, car builders such as Stadler and Siemens make heavy use of multibody simulations. These simulations allow them to model the effects of design choices on vehicle parameters and characteristics like ground vibrations.

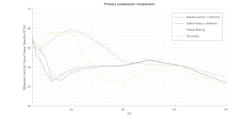

Figure 6 shows an example analysis of primary suspension solutions of varying stiffness and their effect on truck vibration. In this model, the softer primary suspensions (1.2kN/mm and 1.8kN/mm) significantly outperform the stiff rubber bearing (8kN/mm) and no-suspension solutions.

“Of course, it’s always better to have some suspension than none but there is an improvement by a factor of four in terms of force power spectra when moving to a soft suspension,” Perez said.

The same simulation can be used to isolate and model unsprung mass values. In this case, three values are modeled:

- A baseline fully suspended drive

- A partially-suspended/gearbox-unsuspended drive

- An unsuspended drive and motor

Perez notes that in this model, the results for the three variations are similar but there are caveats, the first being, that all variants in the model have resilient wheels, potentially damping the effects of unsuspended components.

“And this model doesn’t give us much information past 40 Hz, likely underestimating the impact of the fully unsuspended drive,” Perez noted.

Models including higher frequencies and tests Stadler has performed indicate that a fully unsuspended drive imparts about 30 percent more vertical dynamic force to the system than baseline for a vehicle moving at 30 mph.

According to Perez, resilient wheels modeled in the same simulation show results in line with those found in FTA documentation. In conjunction with a soft suspension, changing only the resilient wheel variable (solid wheel versus resilient wheel versus ultra-resilient wheel) has very little effect on average vibration for a vehicle already equipped with a soft primary suspension.

“But even in this case, the resilient wheel is still very important for noise control, despite the lesser impact on ground vibrations, as it provides more benefit at higher frequencies,” Perez said.

Car builders also use multibody simulations to model carbody connection types, truck steering configurations and solid axles versus independently rotating wheels. This performance is typically expressed in vibration and noise, truck lateral force values and wheel squeal propensity, respectively.

According to Perez, both models and field tests have shown that independently rotating wheels meet the excitation threshold associated with wheel squeal more frequently than solid-axles under a wide variety of operating conditions.

“Although independently rotating wheels don’t have a profound effect on the lower frequency range affecting ground vibrations, they have a very clear impact on higher frequencies affecting noise generation,” Perez said.

These simulations and data from field testing have helped Stadler develop general internal guidelines for optimized truck designs:

- A soft primary suspension is the main vehicle parameter influencing ground vibrations, followed by a low unsprung mass.

- Ultra-resilient wheels are only justified when combined with stiff primary suspension.

- Friction-free carbody connections produce lower vibration and noise than alternatives.

- Optimized primary suspension steering systems and solid axles provide the best performance in terms of truck lateral forces and noise generation.

Guidelines like these are valuable, especially when backed by simulation and field data. On top of these design considerations, car builders must consider vehicle/track interactions unique to the customer and their operating environment. By incorporating track data into their modeling and simulations, car builders can tailor their design to the true track condition rather than the design spec and ensure that even in the worst-case scenario, the vehicle will meet performance and safety specifications.

Part 2 of this article will continue to follow the discussion on vehicle design, held at the 2023 Wheel/Rail Transit Conference, and will take a closer look at some of the ways in which car builders collect and integrate track data and the importance of taking a holistic approach to vehicle/track interaction.

Jeff Tuzik

Jeff Tuzik is managing editor of Interface Journal. His work appears through an agreement with Wheel/Rail Seminars of which Mass Transit is the Presenting Sponsor.